INTRODUCTION

I was first made aware of Combined Transport by Jon’s nephew Nick. He shared with me that the company is using System Builder/SB+ for their primary business applications. That got my attention because I’ve designed and built some systems with SB+, and I wanted to hear more about how the company uses the unique features of this architecture.

Specifically, I was interested in how their company takes advantage of the multi-value aspect of the Pick System implementation on UniVerse. I’d like to introduce that to Rogue Techies and show them that there’s another, easier—and more user-friendly—way to access data.

| ORIGIN OF THE PICK SYSTEM; Relational vs. non-Relational DBMS The Pick System was originally implemented as GIRLS (Generalized Information Retrieval Language System) on an IBM System/360 in 1965 by Richard Pick and Don Nelson—under contract to the U.S. Army—for the purpose of controlling the inventory of Cheyenne Helicopter parts. |

| After Larry Ellison founded Oracle (originally Relational Software, Inc.) in the late 1970s, the Pick System was regularly panned for “not being a true relational database.” This was viewed as a marketing tactic by Oracle as a way to differentiate their implementation of SQL: Oracle V2 for VAX computers [see paragraph 3 in History Section.] Curiously, SQL also does not conform to Codd’s definition of relational. [Geeks: see also Codd’s 12 Rules.] |

INTRODUCTION TO COMBINED TRANSPORT LOGISTICS GROUP, INC.

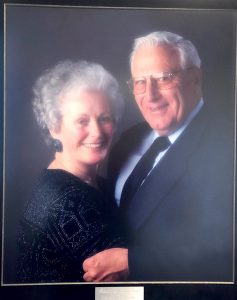

Combined Transport Logistics Group, Inc. (CT) provides transportation services to “anyone who will pay their price.” CT was founded by Richard Card in 1980, “after a long career as a driver, owner-operator and fleet owner helped educate him into the ways of moving freight.”

Richard was at the right place at the right time to obtain a [D.O.T.] license when he made the decision to launch his company. He was also at the right place at the right time to connect with a company that marketed a Pick System-based application package for trucking firms like his.

The Card Family now owns and operates Combined Transport; a multi-million-dollar company that averages 35% annual growth rates. Whew!

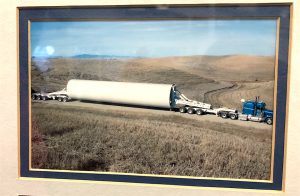

The Mission Statement of Combined Transport is: “to be a growth-oriented provider of a variety of flatbed, heavy and specialized trucking services, always seeking to become the preferred employer for all our ‘customers’ (drivers) and the preferred transportation provider for all of our shippers.”

The following is primarily transcribed narrative from Jon Card, V.P. of Special Projects at Combined Transport, captured during a recent interview at their company headquarters in Central Point. Some minor changes—a word or phrase here and there—were made to translate conversational to narrative format, or to clarify a concept. Enjoy!

The Pick Architecture really is relational, don’t you think?

Jon: It is, the way we think about it. One of the things I really like about the system is, if today I decide I want to add a new field, I simply add a new field.

And, if all of a sudden, we’re putting more characters in a field than we did before then, “hey, no big deal.” Now, if you want to control what you’re putting in, you have to do a few more steps but it’s still very easy to adjust and allow you to make relational connections.

We use multi-value fields a lot … sub-values, not as much. But we actually have one program that uses sub-values quite a bit because it’s used to assign trucks. So, when we have more than one truck assigned to a load [one truck takes the load part way and then another truck takes over; sort of like a tag team process], that becomes a sub-value. It does get a little bit confusing when you’re looking at the guts but if you’re only looking at the output [displays or reports], the format makes perfect sense.

We’ve done a lot of UniVerse work since I’ve been here, which has been 25 years.

Is that your background, specifically?

Jon: (Ha!) I am a self-taught Basic Programmer. And, guess what? UniVerse is in Basic. I simply learned Basic and continued to go on. I had to pick up Unix—or, AIX—because the system is running on AIX—and you have to understand the playground. And that did take me a while … thinking back now … today, I can make some programs very very fast because I know what I’m doing. In the old days, it took me a lot longer to develop and build stuff because I didn’t have anyone to teach me. We had an outside programmer named Dale, and my brother Mike does a little bit of programming but neither one of them took the time to show me, so I had to learn on my own.

When you say you’re programming, are you coding from scratch or are you using the System Builder RAD Tools?

Jon: I’m not programming in System Builder, I’m programming in UniVerse. And, I’m building BP programs from scratch.

So, you’re not starting with the Builder Tools and customizing the stock version with code snippets?

Jon: Sure. There’s some of that. A lot of what I do is to pull up a program that’s doing what I need to do and steal a lot of the code from that module. But we don’t have a library of code snippets that perform exactly what I need to do.

So, you make your own?

Jon: Besides the EDI that I program, I do a lot of reports and data collection; that’s the programming I do. Dale, our outside programmer, is currently doing a lot of System Builder programming for us; taking some of the UniVerse screens and moving them into System Builder so we’re able to do more things with them. We’ve built a complete document imaging system.

Really?!! That’s non-trivial!

Jon: Yes. In System Builder. And, one of the things we can do is: by simply using our flatbed scanner with the associated ScanBuddy software, you click and drag your .pdf into ScanBuddy, select the document type, input your indexing field, and click on Submit to place the document into a queue. Then our document system reads the data and processes the document.

When you say, “reads the data” is it reading the indexing information?

Jon: Yes. We actually create a .csv file that goes along with the .pdf. And then, once it does that, it builds a file with the indexing information and some more information, and simply drops the file on the hard drive, and then it writes the location.

That’s a really valuable tool.

Jon: Absolutely! We’ve been doing our Billing Department processing for three or four years now. We process all our billing paperwork via document imaging. Our entire Billing System is based on it so, if a customer wants to be emailed an invoice, our system automatically goes through the files, collects all the documents, and sends the compilation to the customer.

It’s actually a little bit more work now to mail the invoices. We’ve tried to convert all our customers, but a few insist that we continue to mail invoices. And then, of course, we do EDI. We also use EDI (Electronic Data Interchange) to receive loads. We also use EDI to send in-route updates (truck location status reports) and billing invoices.

You stated that you’ve been at the company for about 25 years. How did you begin your career? What is your background?

Jon: I was an electronics technician in the Navy. I stayed in the Navy for 20 years. And, about 8-9 years into my Navy Tour, I was stationed up here in Oregon at the Navy Bombing Range out near Boardman, south of the Columbia River.

At that bombing range, the Navy was starting to use cameras and computers to calculate the accuracy of bomb hits. They were developing this process on a Tektronix Computer. So what we were doing is using telescopes with degree wheels on them. What you would do is line up two different towers so you had two different angles for the bomb burst, and we had HP Programmable Calculators [click on the link, then scroll down to #3; HP-65] with magnetic strips. So we’d feed in the tower coordinates and then run the calculations to get the answer.

We had the Tektronix Computer, so I printed out the code from the HP and converted that code into Tektronix Basic. The advantage to us was that we also ran remote-controlled dune buggies … they dropped bombs on the dune buggies. You would track the dune buggy and they would say, “Mark!” and you’d click and then you’d locate the bomb burst and click again to get two [reference] points to use in the calculations. And then use the feedback to correct the aim for the pilots. Well, the calculations took so long on the calculator that the next pilot was making his bombing run before we got the answer. And when we did the calculation on the Tektronix Computer, the answer was immediate. That was what got me interested in programming computers. So then I bought a Heathkit Computer and put that together and started doing a little bit of programming and, when I got out of the Navy, that helped launch my programming career. I always loved electronics! But I never had an interest in computers until I was someplace where a computer was being used, and I had a chance to play with it.

Combined Transport was launched by your father?

Jon: Yes. In 1980.

What was his background?

Jon: He was a trucker.

Did he see the opportunity?

Jon: He was a driver for a long time. He went to Alaska and drove on the Pipeline for 2-3 years and then came back and didn’t want to be a trucker anymore. He wanted to be around trucks but he didn’t want to be a driver. He wanted to do more.

Was he employed by a company, or was he independent?

Jon: He was working for Mitchell Brothers for a long time and then, when he went up to Alaska, he didn’t have a choice; you simply drove for them. When he came back, he drove for International Transport and then he started a brokerage with someone else. And, that was right at the time that the D.O.T. started allowing other companies to apply for licensing.

What do you mean?

Jon: For D.O.T. Licenses—trucking licenses—to build a trucking company. Prior to that, you couldn’t get licenses.

Why? Rules?

Jon: Rules. Now, anybody can get a license but back then, it was really hard to get licenses. He was at the right place at the right time, so they got licenses and they started this company. Then the brokerage guy and my father had a falling-out, so my father kept the company and the other guy kept the brokerage.

How does a truck brokerage work? Is that like a contract situation?

Jon: A brokerage simply goes to a shipper and says, “I’ll move that load for you,” and then he has to find a trucker to haul the load. A broker is simply a middleman between the shipper and the trucker. And, that’s all a 3PL (Third Party Logistics company) is now. So, that’s a company that will haul loads for a manufacturing company; they’ll go in and try to take the place of the manufacturer’s shipping guy, and the 3PL will contract with multiple carriers. The carriers will bill the 3PL and the 3PL will bill the manufacturers. That’s sort of what everyone is trying to do; either you’re a small company and you’ve got to work for somebody else or you’re a bigger company and want to convince the manufacturer that you’ll take care of all their freight and, what we can’t move, we’ll hire someone else to move.

Did you attend Ray’s Tech Talk on Automating Retail?

Jon: No. Only the NextGen911 Talk by Corey.

The reason I ask is: Ray was explaining to us how retail corporations have their own distribution centers; obviously, Amazon, Target, WalMart. But then I asked about independent distributors. Ray responded that those distributors generally work with smaller retail outlets. Is that what you find, also?

Jon: That’s true … like Caterpillar; Caterpillar is a huge company. We did a bid process with them and won certain lanes, so we cover those lanes for Caterpillar. [Lanes = Routes; e.g., Illinois to West Coast.] And a lane can be very narrow (zip code > zip code) or it might be an entire state; it simply depends on how they segment their transportation needs. A lot of companies have repeat moves to the same area. For example, we haul for Resers. They know they are going to ship 100 truckloads a year to the L.A. Distribution Center.

For a grocery store?

Jon: Say it’s Safeway Distribution Center. We ship from point of origin to Safeway’s L.A. Distribution Center and then Safeway transports the products from their Distribution Center to the stores.

So you’re basically an independent (trucking) contractor for the various independent distributors. Great business model!

Jon: Not necessarily only distributors. We also do dedicated hauling. We might contract with a company to provide them 15 trucks, and they can do whatever they want to do with those 15 trucks but they have to make a certain amount of revenue, per truck, per month—and, if they don’t make their target, they must make up the difference. [This is an example of a fixed-price bid.]

So, when you do something like a fixed-price bid, are you providing both the truck and the driver?

Jon: Yes.

And is that driver an independent contractor to you or to them?

Jon: No. Not necessarily. The driver could own their own truck, and we hire the truck and the driver comes with the truck—or, provides a driver for their truck. We call that an Owner Operator. But when we give them a dedicated truck/driver, it’s normally based out of a single area like Fresno or Chicago, and then the driver only carries loads out of that “base” area and then returns to the base to pick up the next load. These point-to-point round-trip contracts are usually for one or two years at a time.

Am I missing anything about the business model?

Jon: No. We’ll haul for anybody. So if someone wants to hire one of our trucks and is willing to pay our price, we might make it C.O.D. because our Credit Person looks very closely at the deal; that’s very important because, if you haul a big load and don’t get paid for it, that’s a big problem. So we do a lot of C.O.D.s and even some credit card payments for smaller companies [who may want to rack up some airline miles by paying with a credit card.] [Reference for Lane Bidding and calculating costs of a trip: https://smallbusiness.chron.com/trucking-business-contract-bid-15204.html]

GOING PAPERLESS

So for us, what we’ve tried to do … one of our kicks is to focus on reducing paper. We print 80,000 copies per month. But it has decreased from what it used to be.

Our Accounting & Billing Department uses very little paper; they do almost all EDI. So a lot of the reports we now generate, instead of sending them to the printer, we email them. Granted, the recipient might still print them out; however, email makes it easier to skim through the list and selectively print what you really need to see on paper. And, we’ve moved into more Excel-type tab-delimited / comma-delimited files, simply because people want to manipulate the data, and that’s easier to do in an Excel spreadsheet.

I prefer tab-delimited spreadsheets; they’re easy to work with. The problem with tab-delimited is: their default for Excel is .txt format. So I send out the spreadsheet in .xls format and then, when the file is opened, Excel informs you that this is a corrupted spreadsheet and asks if you want to continue. When you say, “yes,” the spreadsheet works just fine. So, for our customers, I have a tendency to do more .csv for them because the “corrupted” message is not displayed. But I have our in-house people trained to override the error message.

So we do a ton of emails; email warnings, alerts, lots of stuff via email. We send emails to our brokers two or three times per day with lists of our available loads. We post our available loads on our website.

You just raised a red flag here. How’s your security?

Jon: We host our website offsite. And I ftp the files to the website.

I mean, as far as … I’m thinking back to a Cybersecurity Seminar that CORE hosted a while back, and one of the things they commented on was being spoofed by an entity that hijacked a trusted partner’s email address and then sent an email stating that their address for wire transfer payments had changed. Turned out to be ransomware. Poof! Spoof! Do you run into any of that with all this electronic communication you’re doing?

Jon: Sure.

Ah. Who’s handling that? Or, do you have an outside contractor?

Jon: We use a program called KnowBe4 for Security Awareness Training. They are a spoofing company that sends spoofs to us. We break-up our company into divisions and anyone who gets caught answering a phishing email has to take some training classes from this company.

Great! I love hearing about that!

Jon: And when we hire somebody, we have them take some training classes.

That’s great! I’m so happy to hear that there is pro-active training going on with new hires; especially younger people who are so used to putting everything out there on the Web, without giving any thought to how that information might be used to bring down a whole company.

Jon: We’ve had a couple of interesting occurrences. I got caught on one…someone imitated my brother Mike, who happened to be out of town at the time. The email requested information about our operating processes. So I replied to the first email but quit replying after that, and we did talk, in house, and we could see where they were trying to set us up to do a wire transfer of some sort. But, at least—for our company—we’re all here. Marji’s our C.F.O. and we talk all the time, so if Marji received an email like that, she’d simply come to my office and ask about the request.

Where we’ve had more of a problem is with our Customer Service / Driver Service Department that repairs the trucks over the road [sort of like Triple A for Truckers] they fix anything that happens to a trucker while he’s on the road. And they’re our own people. If we get a call from a law enforcement agency that notifies us one of our trucks has been involved in an accident, well … we’ve been scammed two or three times. And, each time, we investigate. We try to educate all the people along the communication chain so that doesn’t happen again.

But it’s so easy to fall for some of these scams. The scammers are very smart people; that’s the one thing I took away from that Cybersecurity Seminar.

Jon: Yes. They do their due diligence; they track down and figure out our load numbers and other types of information so they can read it back to the staff. Or, they’ll call and get the information and then call back later and speak with someone else and, because they seem to know what they’re talking about, they seem believable.

We pay by ComCheck [a product offered to fleet operators by ComData], which we use for our fuel payments. It’s basically a check that you can register and give to anybody in the trucking industry or take it to a bank, sort of like a certified check. Plus, we also do credit card payments. The one thing that is nice is that most of our payments are by virtual MasterCard; one-time payment cards similar to a fixed amount debit card. You simply register the card and add a fixed amount to the card; that’s the maximum amount that can be charged to that card.

This sounds like a similar format to that used by ApplePay where there is end-to-end encryption for each transaction.

Jon: We simply log onto the ComData website and register a card; each of our users are authorized to spend a certain amount of dollars per day, per transaction. The card can be narrowed-down by number of transactions or number of dollars; insured by MasterCard.

Back to UniVerse and how you’re using it.

Jon: Well, everyone here uses UniVerse, whether it’s Billing or Accounting or…whatever. It’s a full company package.

How about logistics? Do you have any software applications that are specific to logistics, per se, or is that process fully-integrated into the overall company processes?

Jon: I generate automated reports in either .pdf, or .csv. We will send these reports to the customer listing each load that is in-route. We can also list all pending loads.

We use GPS data to give estimated miles to delivery and warnings if we are late.

Customers can also use our website to track their loads; they just need either our load number or the their own P.O.Number.

Our Credit/billing department can generate an outstanding list for each vendor that we automatically email out monthly or on request.

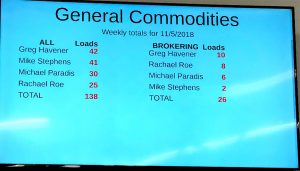

Our dispatchers have regions they cover. Some only have half of a state (California) others have 5 to 10 states. We have four groups of dispatchers each group covers all 48 states and Canada: Glass (with only three dispatchers), Heavy Haul, General Commodities, and Blackwell (handle reefers [Refrigerated trailers]).

Each region has a unique number. The dispatchers get a list of all trucks inbound to their region and the list also has driver time off requests and equipment maintenance requirement. The dispatcher manually matches the existing loads to the inbound drivers.

So, not currently automated but we just had a meeting yesterday discussing automation. We decided that some loads/drivers could be automated but others would not be. We plan on looking at that process more in depth next year.

Interrupt: Birthday Card Folder; lots of people with birthdays. How many people work at your company?

Jon: There are two separate buildings. About 110 people work in the office. And then we have around 400 drivers.

And, are you doing payroll out of your company business software?

Jon: Yes. We build the payroll data via UniVerse and then upload the raw data into ADP (Automatic Data Processing) and then ADP does all the taxes and other withholding, and does direct deposit, and then returns files to us for distribution of paychecks to drivers. If a driver wants to see an actual pay stub in addition to the email notification, they log into ADP. That whole process is handled via UniVerse.

Is your UniVerse application software all custom?

Jon: Yes. We bought a trucking software package back in the late ’80s or early ’90s that was written by ISI out of Colorado. And, after that, they came out with a document imaging system.

Have you customized their package?

Jon: Oh, tons. Tons. Completely customized. Good bones. Their maintenance package was the worst! The guys didn’t document that package at all, and they used abbreviated variables instead of descriptive variables and explanatory comments, making their code much more difficult to read.

Yes. And getting inside the mind of a coder like that can be a big challenge.

Jon: Yes. So, our payroll package is completely new because we didn’t use the payroll package that came with the original system. Drivers get paid by the mile, or they are salaried. But we also pay them for other things: If they’re not a glass driver and they have to tarp the load, they get paid for that; if they go to Canada, they get paid for that; if they make an extra stop, they get paid for that; if they set up the racks for a glass load, they get paid for that; if they take down the racks for a glass load, they get paid for that; if they have extra glass on the load which requires an extra tarp, they get paid extra tarp pay; if they get stuck at a customer site, they get paid for detention.

We also have a few lanes that are guaranteed miles so, for example, we’ll tell a driver that we guarantee they’ll drive 9500 miles per month. So, on the second payroll of the month, we calculate their miles and, if they don’t have the guaranteed mileage, we make up for that.

The way their salaries are, line haul gets a certain amount of money and, if they go to Canada, we pay them an extra two cents per mile. For every year they’ve been with the company, we pay them an extra half-cent per mile. We also pay them four cents for doing a good job; incentive. So, if they have glass breakage or other damage, we deduct an amount from that four-cent incentive pay. But we can’t take their basic salary. So our custom payroll package calculates all those add-ons and deductions. We also have a 400-mile mini; we guarantee that a driver’s first load of the day will be at least 400 miles and, if it’s not, we pay them for 400 miles.

Is this all union rules?

Jon: No.

So, this is your company deciding that this policy is what’s fair for the drivers.

Jon: Absolutely!

I love that!

SUMMARY

Combined Transport is an owner-built company that has weathered decades of challenges in a very competitive market by doing what’s right for their very talented staff, customers (truckers) and shippers. Their success seems to be well-deserved!

Thanks to Jon Card for his time—and for being so open about the technical side of their business operations!

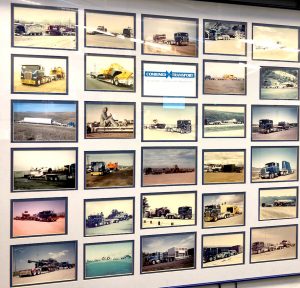

FACILITY TOUR

Following the interview, Jon took me on a tour of the Headquarters Facility. Here is a photo album of the grounds.

The Heavy Haul Photo Gallery provides historical photos to remind everyone of past achievements:

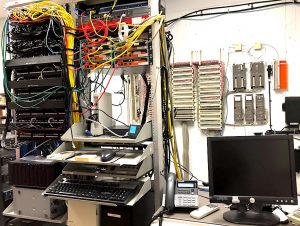

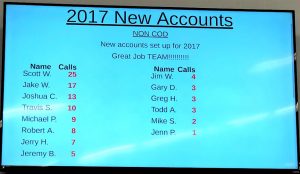

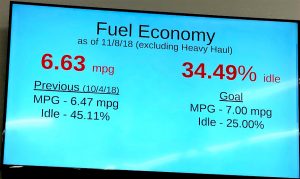

Jon’s nephew, Nick used Raspberry Pi’s to produce the tote board displays that provide real-time status information to everyone in the building:

Author: Karen

Vetted By: Jon

Written: 12/3/18

Published: 12/4/18

Copyright©2018, FPP, LLC. All rights reserved.